Manufacturing Digital Transformation Framework

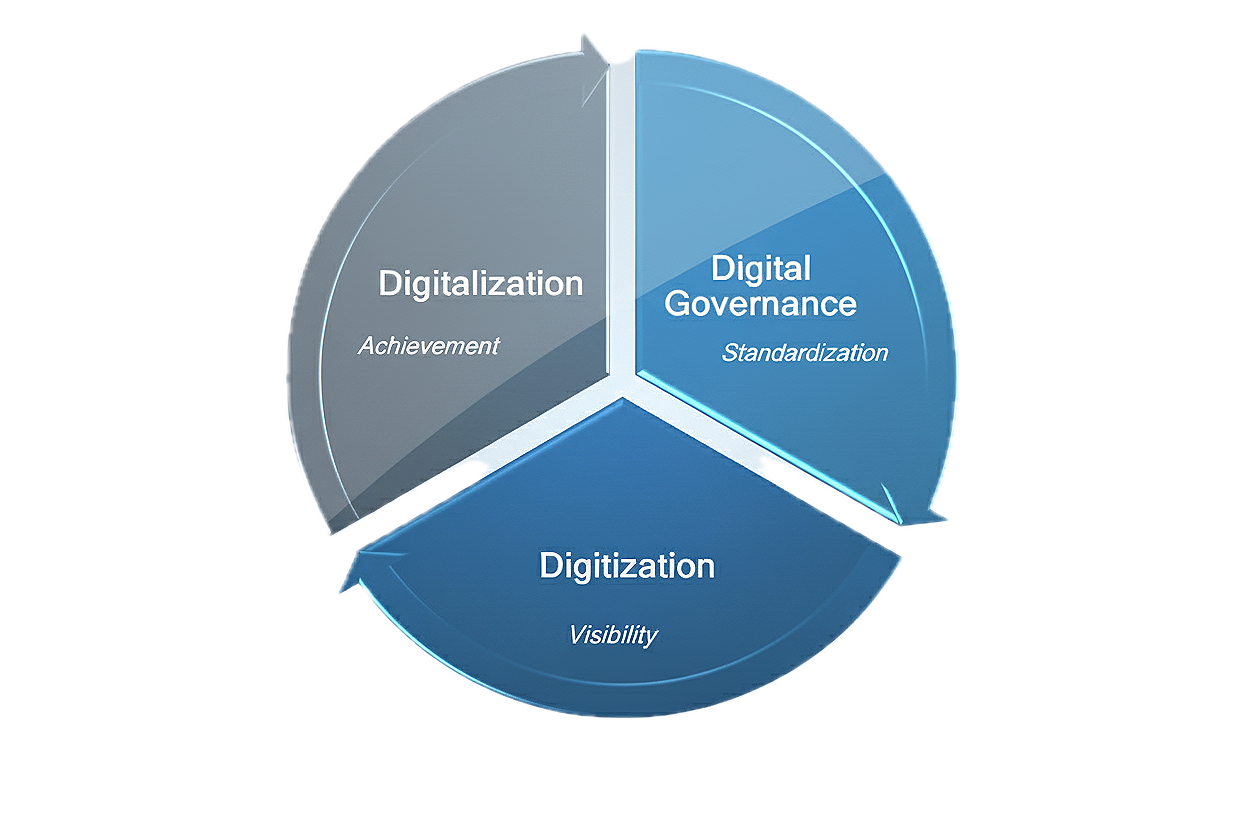

Digital transformation is a journey and approaches with architectural mind set and business context to sustain the business and grow for the future to make contribution to our world through implementing lean and intelligent manufacturing environment. Digital Transformation starts from future target image of the company with understanding on demand for data and its usage for continuous improvement. Digital Transformation Framework that helps and facilitates this journey consists of 3 phases, Digital Governance, Digitization and Digitalization.

Standardize facts to digital format

The foundational step for digital transformation is to build “Digital Governance” that defines data that represents activities with input and output in real business world. In other words, data is to the fact translated to digital format to understand man, machine, material, method and environment in factory to detect and solve the problem/risk or to make decisions to run business in optimal way. The data needs to be standardized in terms of business context. In addition to standardization of data for digitalization, security of data need to be always considered with access level and protection from external threats. Technologies for transforming facts to data need to be standardized as well to manage the journey at optimal cost and low risk.

Transform facts to data and make it visible

Once data is defined, the facts in the business world need to be digitized, so called “Digitization”. it is necessary to translate them into digital format to allow us to see and analyze the facts. Any problem or risk that cannot be seen cannot be solved or eliminated and our business is exposed to risk all the time. In manufacturing process especially, facts from 4M1E(Man, Machine, Material, Method and Environment) need to be digitized into data for visualization and analysis. Digitization in manufacturing process can be realized efficient devices and sensors to collect data from production equipment, operators and manufacturing environment and value chain processes without interrupting current manufacturing processes. Traditional automation technologies are not affordable since it requires huge investment and takes long to get there, so innovative and lean mindset are required to make it affordable.

Realize autonomous manufacturing vision

Data collected and visualized need to be easily visualized and analyzed and decisions would be made autonomously with minimum intervention of human beings. This is so called “Digitalization”, the ultimate step in digital transformation journey. To make effective and efficient in this phase, the engagement of employees with use cases that can be digitalized and automated is crucial. It is necessary to eliminate big picture or ambiguous target, but it is necessary to take action and realize the benefit to the business in low hanging fruit approach.

Tools to support for the journey

To realize digital transformation journey, we need to adapt “Digital Technologies” into the business. Machine integration technologies allow to digitize the vertical way while ERP allows to digitize value chain process in efficient way. Data streaming and big data platform, LLM/RAG are the fundamental assets for autonomous operation of business and AI agent services with machine learning is the application tool that consumes the fundamental asset for realizing the autonomous operation of business.